In de windindustrie hebben onze moderne en innovatieve inductiesystemen zich bewezen over de hele wereld. Met name voor montage en demontage van lagers, lager huizen en koppelingen.

Een greep uit ons klantenbestand: General Electric, Siemens Gamesa, Vestas, Winergy Flender, ZF Wind Power, Moventas, Lagerwey, Availon.

Voorbeeldtoepassingen

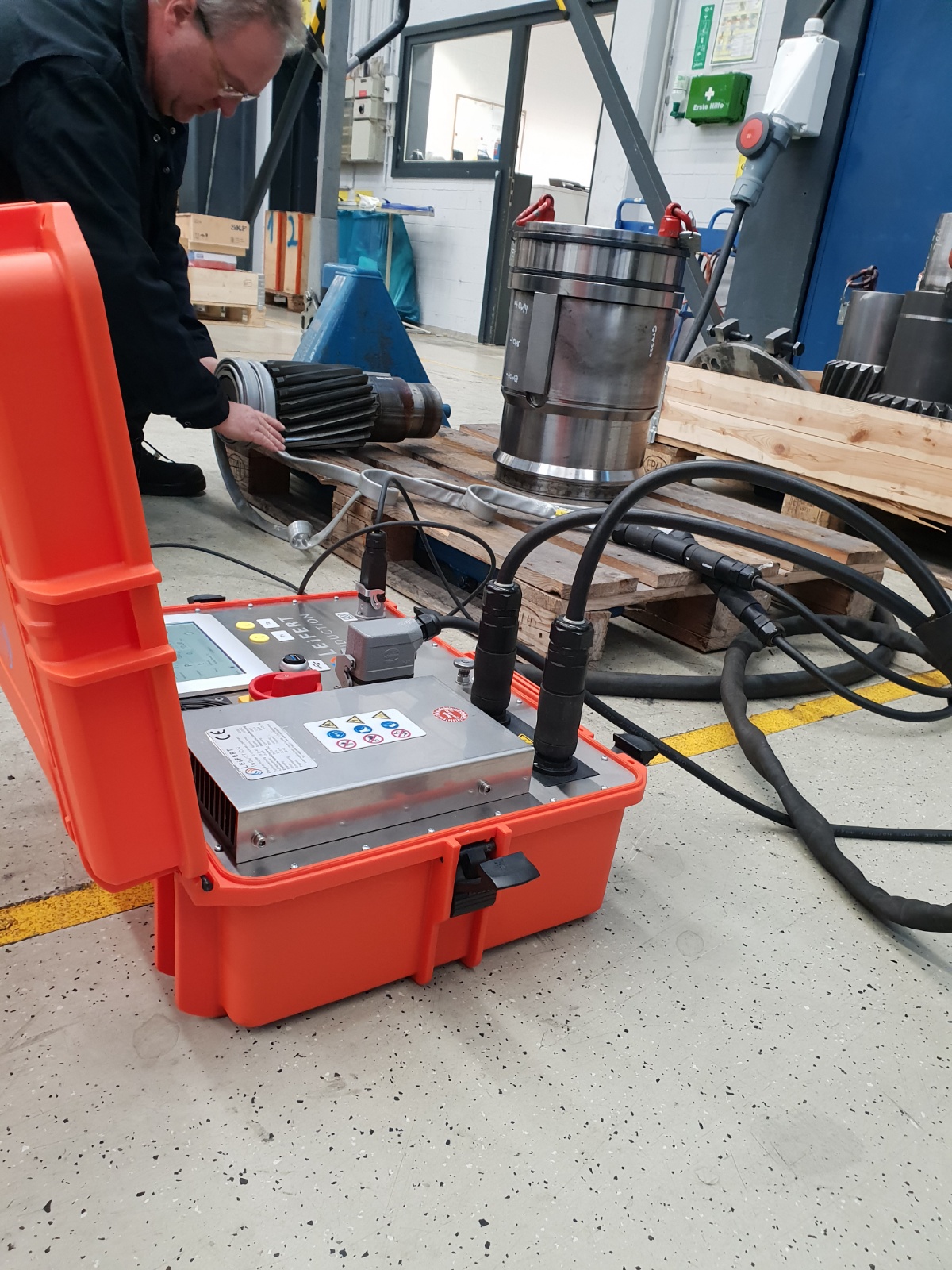

- Assemblage van windturbines

- Montage en demontage van (hoofd)lagers, sealing rings, lagerhuizen

- Verwarmen van holle assen gearbox

- Dubbel gelagerd Axiaal lager (2.5 Ton) in 20 minuten gedemonteerd

- Voordelen in één oogopslag

Voordelen in één oogopslag

- Kortere opwarm- én afkoeltijden

- Milieuvriendelijk en energiebesparend

- 100% Reproduceerbare verhittingscyclus

- Veilig, laag geluidsniveau en eenvoudige bediening

- Download uw verhittingscyclus t.b.v. kwaliteitscontrole

- Volledig gasvrije verwarmingsmethode

Klanten waar we trots op zijn