Productie in de automobielindustrie vraagt om korte takt-tijden. Met onze innovatieve inductietoepassingen word het productieproces versneld door gecontroleerd en effectief te verwarmen.

Een greep uit ons klantenbestand: Daimler, Scania, MAN, Volkswagen, Porsche, Tesla, Bridgestone

Voorbeeldtoepassingen

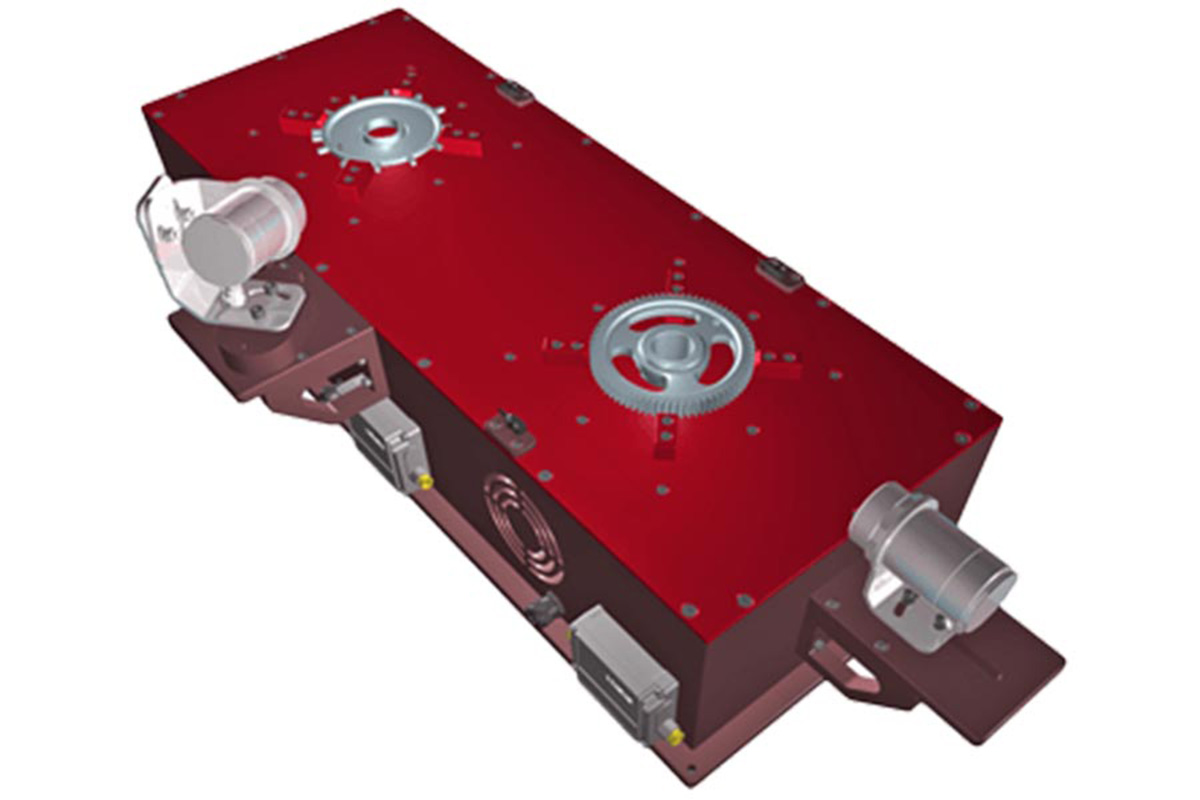

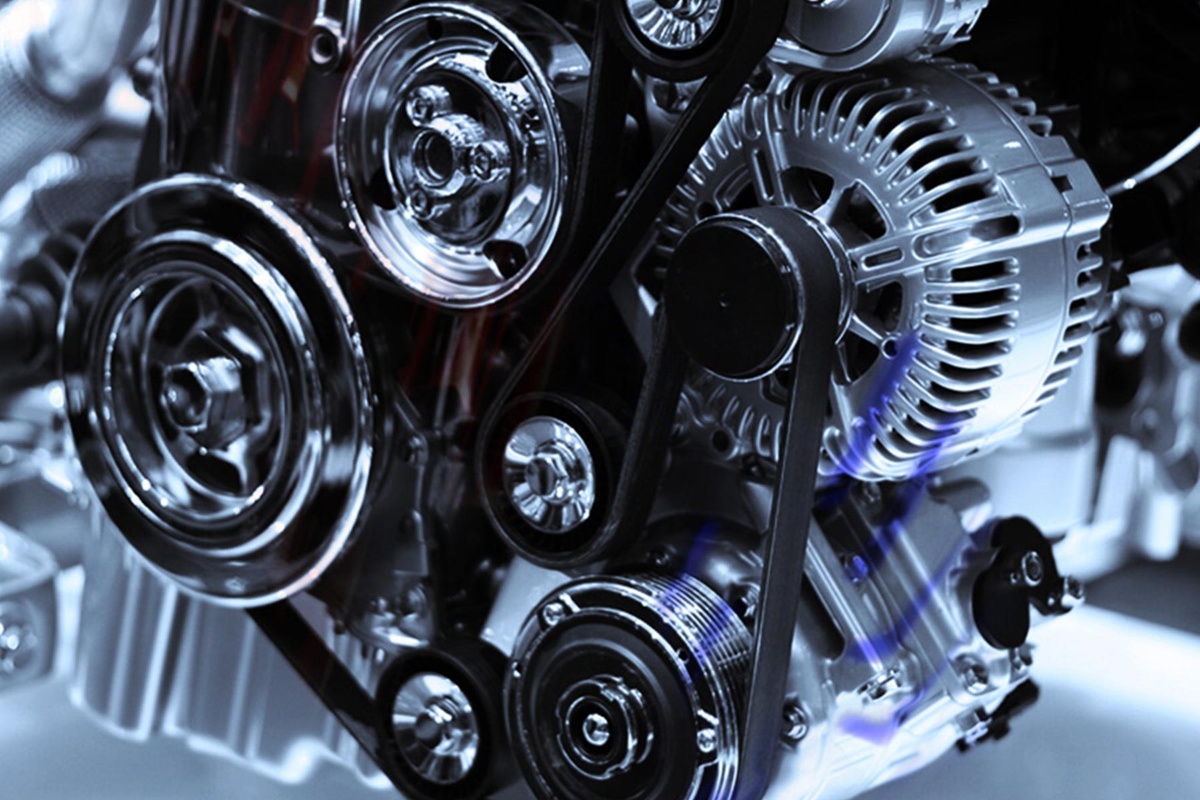

- Montage van nokkenassen en tandwielen

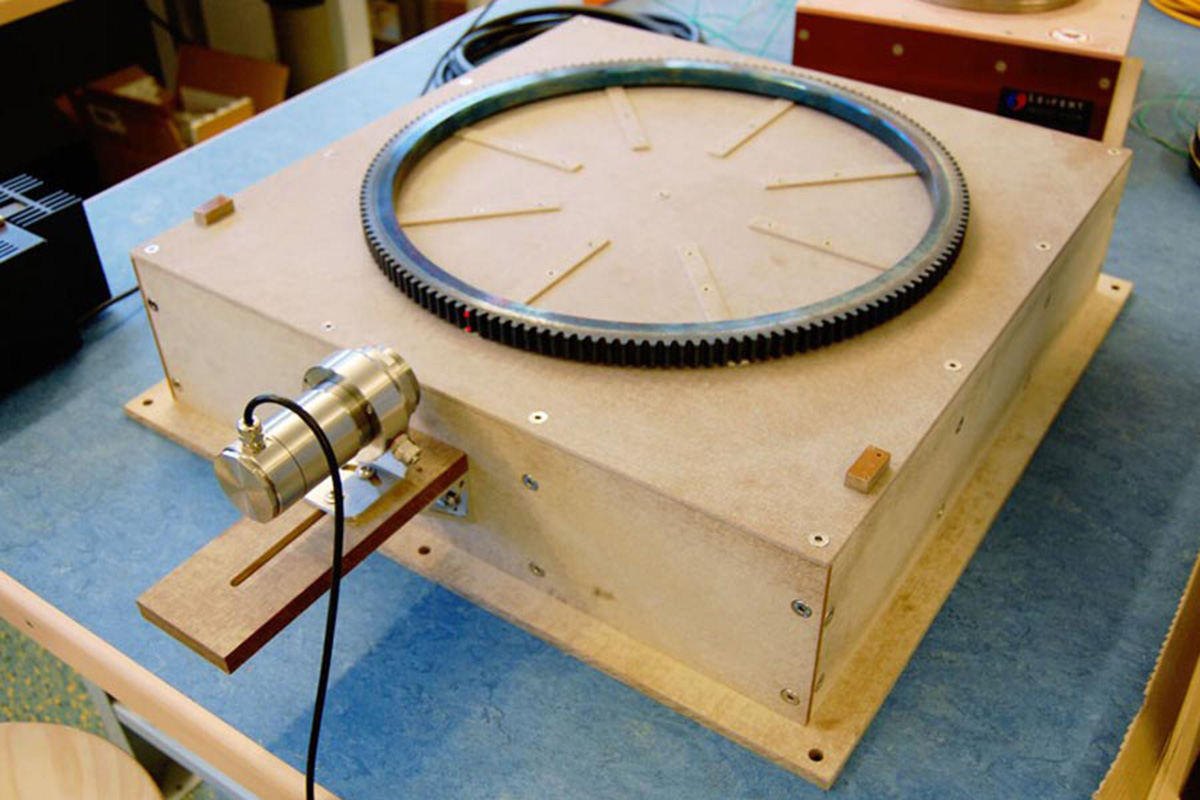

- Montage van starterkransen binnen 20 seconden

- Harsen, vulkaniseren en lijmen t.b.v. E-motoren (hybride motoren)

- Montage en demontage van aandrijfcomponenten

Voordelen in één oogopslag

- Razendsnel, gecontroleerd en vlamvrij

- Milieuvriendelijk en energiebesparend

- 100% Reproduceerbare verhittingscyclus

- Veilig, laag geluidsniveau en eenvoudige bediening

- Download uw verhittingscyclus t.b.v. kwaliteitscontrole

Klanten waar we trots op zijn